Description

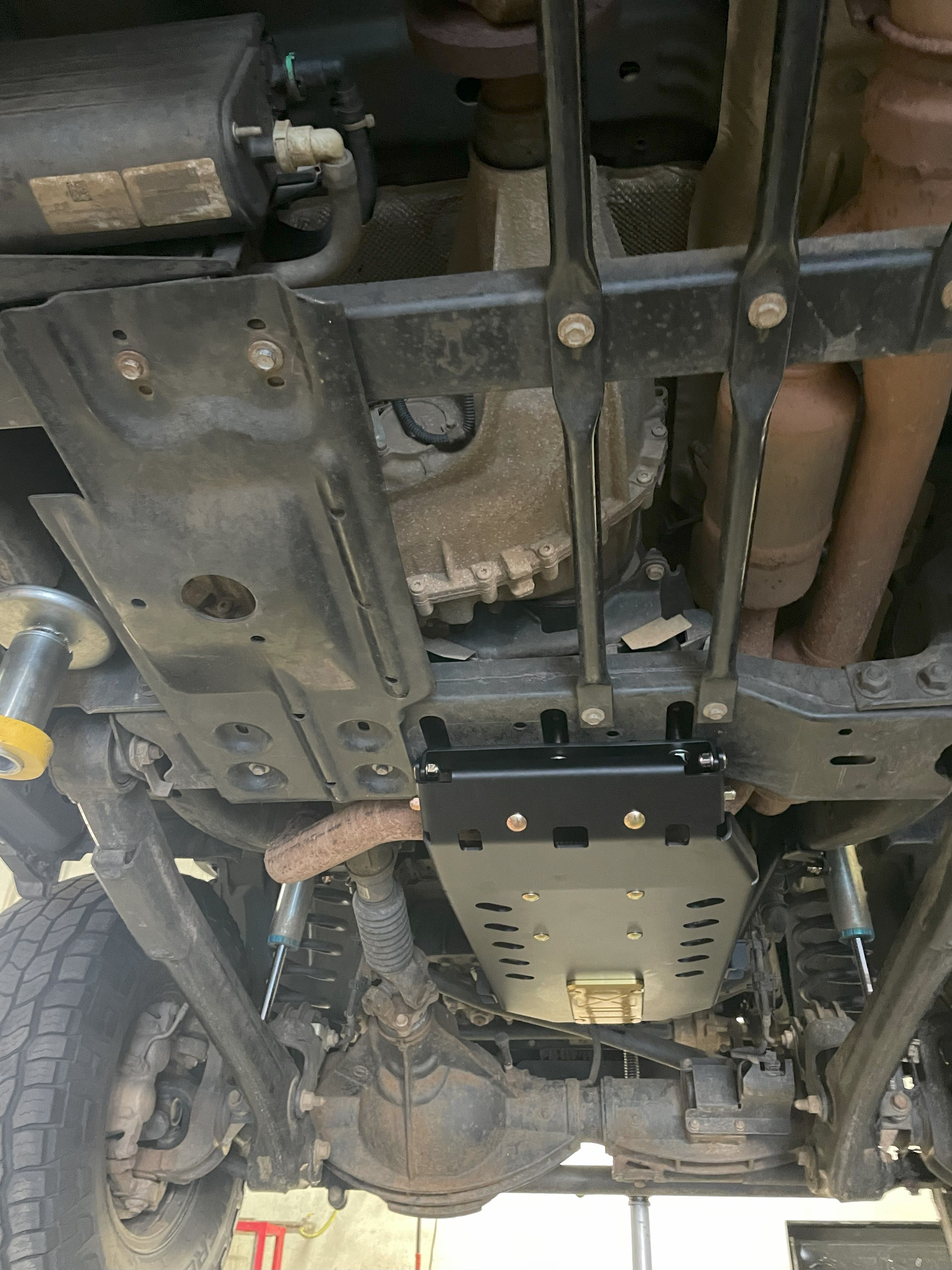

Following on the heels of our bombproof first generation skid plate, our Generation 2 system has been engineered from the ground-up to incorporate unique features and improvements guided by years of feedback and experience. Our new design builds on extraordinarily robust construction by offering user friendly installation, unhindered service and maintenance, and compatibility with the limited existing OEM protection elements.

This system is among the most innovative and heavily engineered armor systems ever produced.

Protected Elements: This skid plate system protects the Engine, Transmission, Exhaust Crossover, Transmission cooling lines, and Transmission shift linkage, and reinforces the Transmission Crossmember.

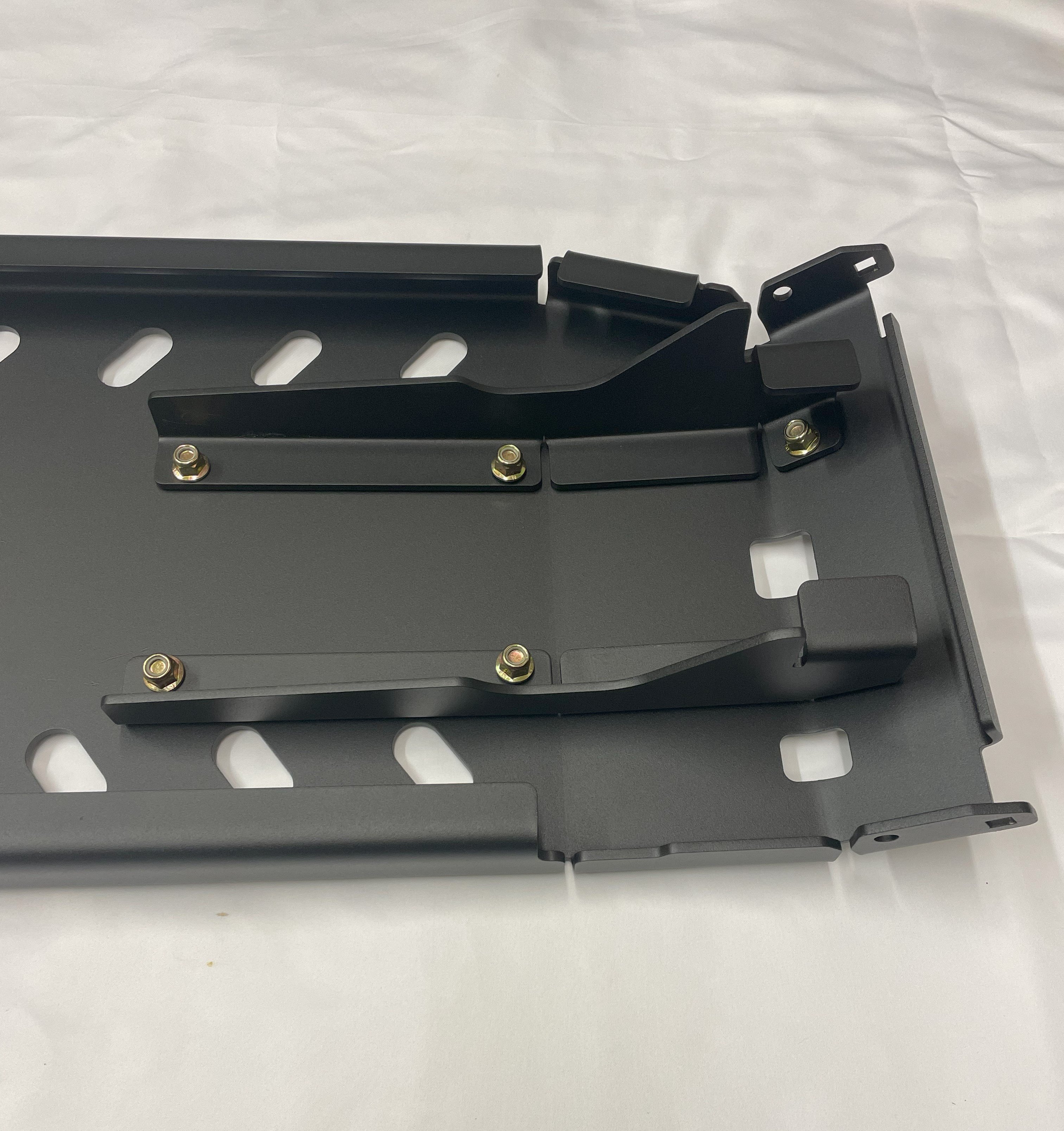

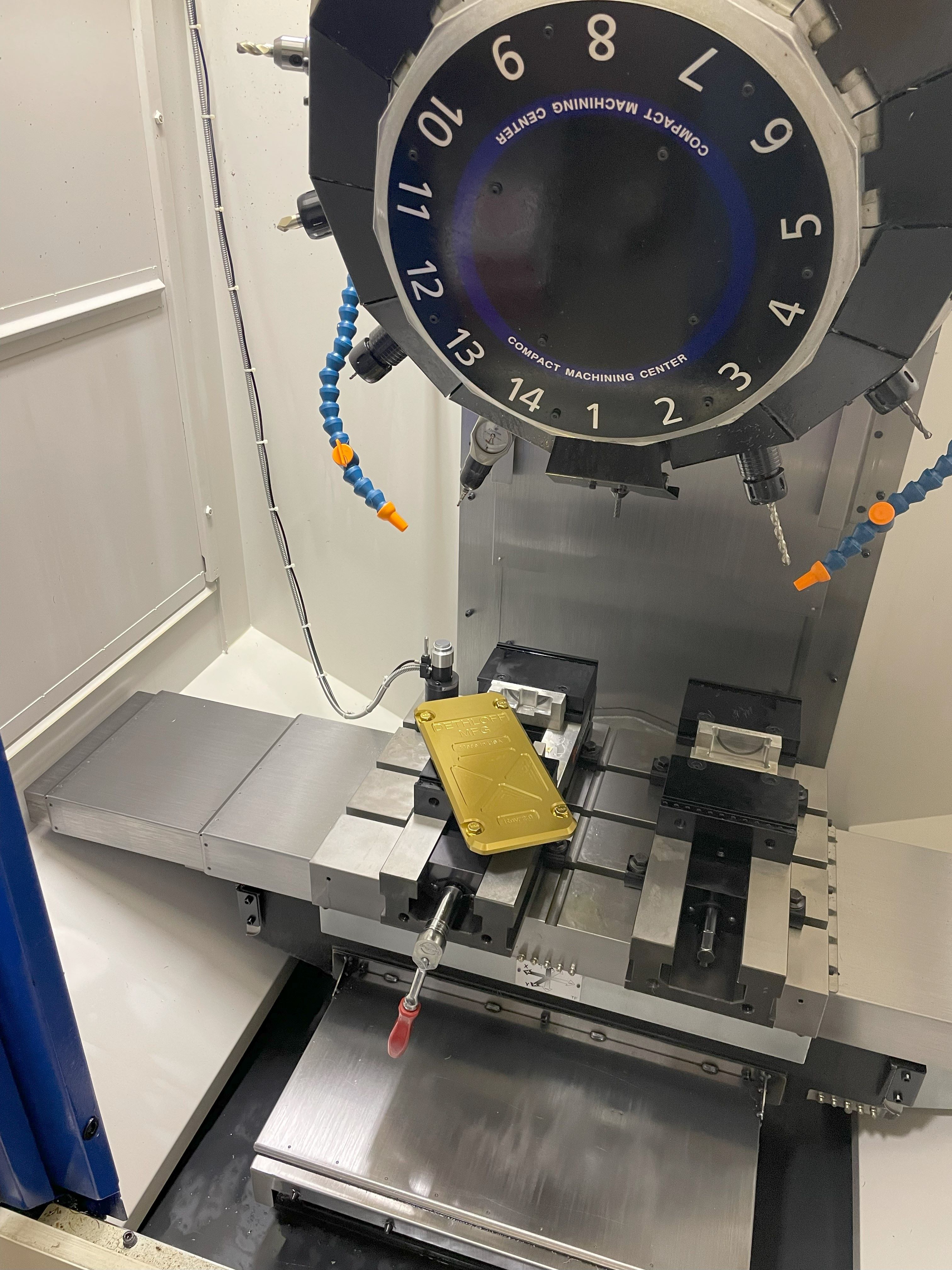

Construction: The standard in-use weight of the Ram HD platform begins around 8,500lbs and grows from there. This application absolutely demands the use of steel vs. lighter materials such as aluminum, and the material selection and design characteristics are derived directly from our extensive testing and feedback. Made to protect the most critical – and critically exposed- parts of the Ram HD trucks, this skid plate is manufactured from laser cut & CNC formed 3/16″ steel plate and CNC formed 1.500″x.188″ DOM steel tubing. The perimeter of the skid plate is fully structural and is formed into a C-channel shape in order to provide incredible strength and to prevent flange blowout under load. Unlike single-edge “L” flanges which will simply bow outwards and collapse when they take a heavy load, C-channel structures are highly resistant to flange failure and maintain full strength under high loads. Based on the feedback and experience of prior models, an internal beam structure was added to reinforce the areas where ~98%+ of impacts occur. The belly of the skid plate is kept smooth and is angled slightly upwards at both ends in order to allow a smooth approach & departure in either direction of travel and to produce zero snag hazards. The rear mounting bracket adds a reinforcing flange to the front to provide additional structure to the OEM transmission crossmember and to provide a positive engagement surface. The internal beams produce a coupling action with the main rear bracket & transmission crossmember; under the slightest impact force the internal beams transfer all impact load vertically and rearward into the reinforced crossmember. Through this system the hinged servicing mechanism of the skid plate carries almost zero load under impact. The forward mounts secure in a sandwich-style mount similar to the most robust rock rails; the main bolts secure through OEM frame holes, and the lower mounting bolts couple under the frame in order to preload the mounting brackets. By doing so, impact load is transferred into the CNC formed flanges rather than through the fasteners.

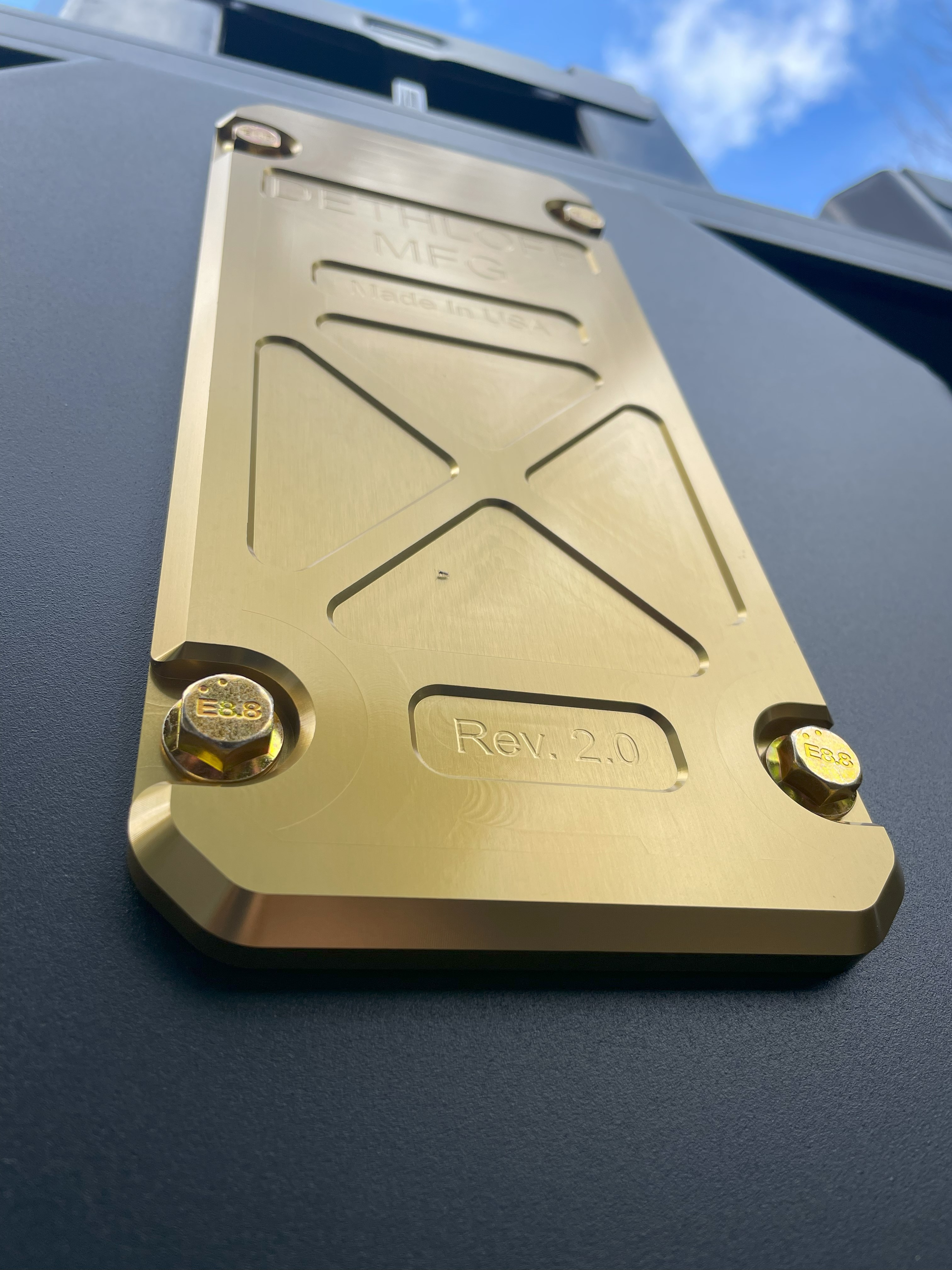

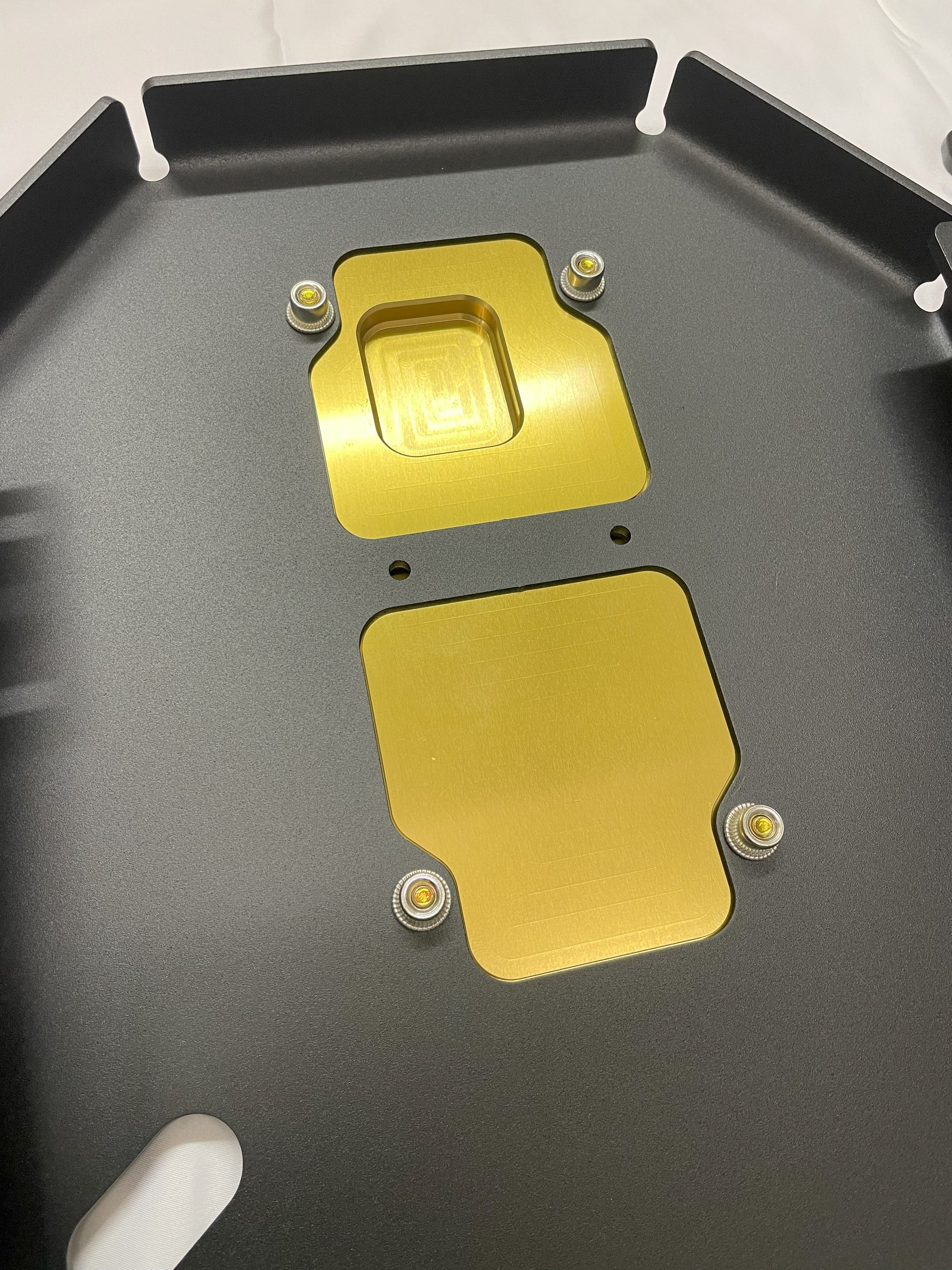

Finish: Steel parts are media blasted, phosphated, primer coated, and finish powder coated for an extremely durable and smooth surface. Our aluminum elements are bright-etched and Gold anodized for a beautiful and unique finish.

Service: Changing engine & transmission fluids is as easy as possible. The oil drain for the engine is exposed by removing the CNC machined cover plate, which uses the same 13mm drive size as the OEM oil drain bolt (13mm on Hemi, 3/8″ square drive on Cummins). The oil drain cap has a pocket machined under the diesel engine drain port to offer additional clearance for Fumoto valves to offer extra clearance during severe impacts. To change the transmission fluid & filter, the skid plate incorporates a drop-away access system – the first of its kind. The forward leg bolts & the rear load bolts are removed, and the entire skid plate body hinges away while staying fully retained to the rear main bracket. This permits the entire oil & filter change process to be completed without needing to remove and replace any section of the system.

Hazard Prevention: An issue common to many skid plates used in offroad applications, whether due to the chassis location they have to work with, or due simply to poor design, is the buildup of brush on top of the skid plates. This can produce a fire hazard if the brush is able to build up between the skid plate and an exhaust component. In order to mitigate this, we have taken several steps: First; the skid plate rests at an up-angle so that it’s leading edge is above the base of the front axle and so that it has a smooth engagement with brush, causing the brush to be pressed down rather than sheared off against the front of the skid plate. Second; the skid plate perimeter is formed into a C-channel structure – this is both to prevent structural blowout of the flanges under impact, and to provide smooth edges along the perimeter to prevent the shearing of brush. Third; the internal structural beams have a leading edge at a safe distance from the exhaust that catches any brush that makes it onto the skid plate.

Important Notes:

- Aftermarket Deep Transmission Pans: This skid plates offers a large amount of space from the transmissions found under the 2500/3500 gas trucks (66RFE & 8HP75) and these should be able to run the deepest oil pans without issue. The Aisin transmission and the G56 manual transmission sit very low in the chassis and this needs to be taken into account. If you wish to fit oil cooling blocks to the G56 transmission, or wish to run a deep oil pan on the Aisin transmission (3500 HO Cummins & available on all 3500 Cab & Chassis), you MUST confirm that you have appropriate clearance between the oil pan and the skid plate. Some aftermarket deep transmission pans for the Aisin sit VERY LOW, and YOU must confirm that there is enough clearance to fit the skid plate & deep pan together.

- Other Aftermarket Parts: Our design allows a lot of room for integration with other aftermarket parts, but due to the number, variety, and continuing innovation of new products on the aftermarket, we cannot confirm that other companies’ aftermarket parts will integrate with our parts. The responsibility to check fitment, cycle suspension, ensure appropriate clearances due to motor mount deflection & impact deflection, etc. are always incumbent on the end-user.

- Safety & Prudence: Every truck and every application are different. Our design incorporates features intended to offer robust protection for your drivetrain, easy service, and to prevent hazards such as brush buildup. With that said it is still a good idea to occasionally inspect any aftermarket part and to ensure that you do not have any brush buildup near exhaust components. This skid plate has easy service features and drains that make it easy to keep clean, and it is easy to visually inspect the top for brush buildup without removing anything.